Ⅰ.Machine Description

Disposable non woven slipper making machine has automatic feeding system, automatic upper folding positioning system, ultrasonic welding system and rolling cutting mechanism, photoelectric detection system etc.It is advanced and reliable in technology, simple and safe in operation. It will completely replace the old complex process flow, save labor costs for users, reduce environmental pollution, improve product quality and output, and cover a small area, which is economical and practical. It also can add printing function according to your requirement.

Ⅱ.Schematic diagram

Machine process:

Material feeding - traction - welding and forming - cutting - conveyor belt output

2. Features

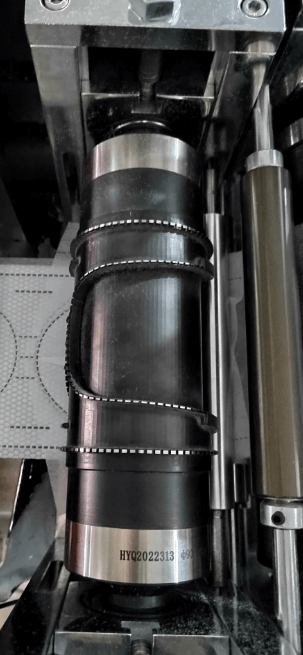

1. Using the ultrasonic and special steel roller,sewn without thread&heating.

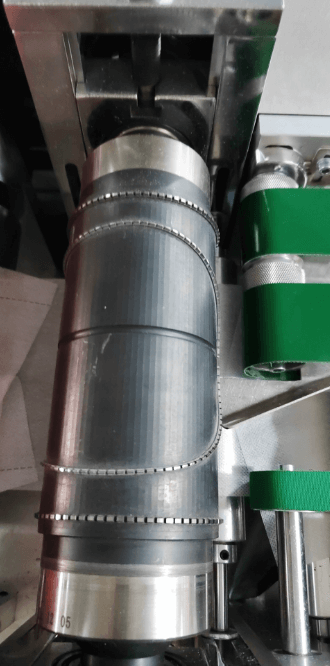

2. Use separate steel cutting mould,10times longer life than traditional model.More flat,more beautiful, no wrinkles.

3. Machine with auto-ultrasonic welding function,more efficiency and easy operation.

4. Slipper size(L*W):270*110mm,other sizes according to our customers;

5. Machine with auto-counting and will stop once reach setting production.

6. Machine with 2nos. Fabric feeding roll,each roll tension can be adjusted separately.

7. Suitable for PP non-woven fabric,Hot air/Air through non-woven, SAP paper, SS hydrophilic non-woven etc.

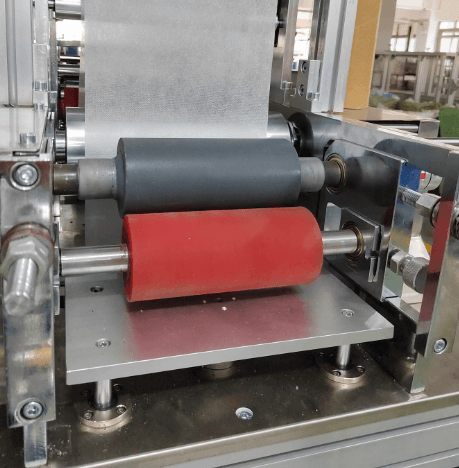

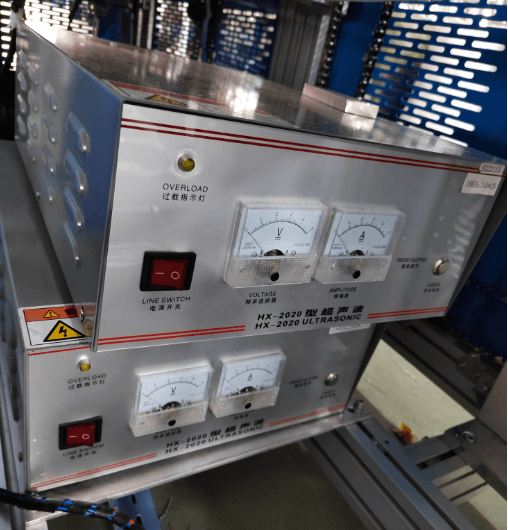

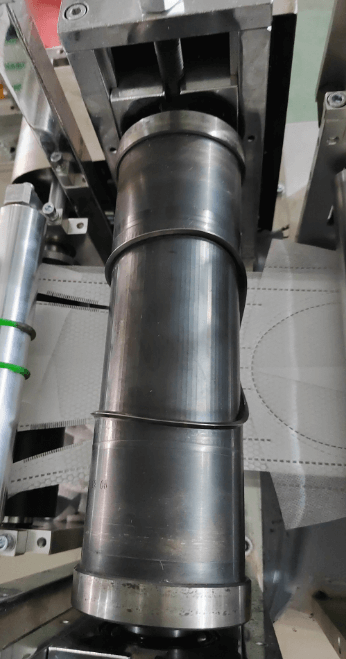

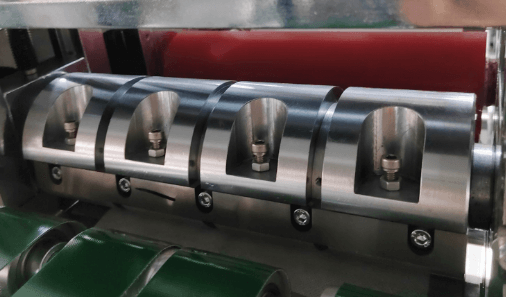

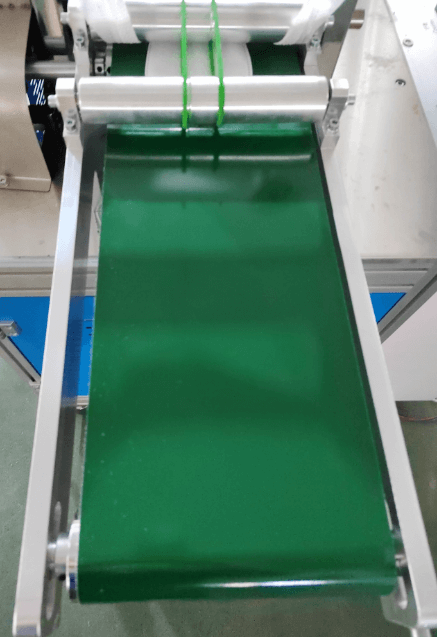

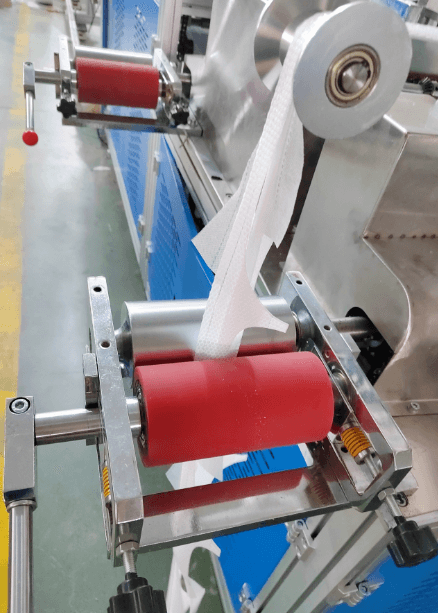

3. Detail photo

6. Main configuration

|

Name |

Remark |

Quantity |

Place |

Picture |

|

Feeding device |

|

1set |

China |

|

|

Traction roll device |

|

6sets |

China |

|

|

Ultrasonic system |

|

2sets |

China |

|

|

Welding device |

|

2sets |

China

|

|

|

Cutter device

|

|

3sets

|

China

|

|

|

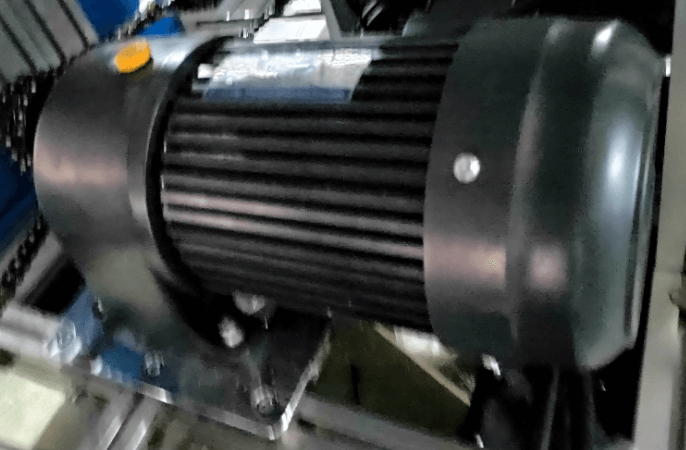

Motor |

1.5kw |

1pc |

China |

|

|

Conveyor belt |

|

2sets |

China |

|

|

Electrical equipment |

|

1set |

China |

|

|

Control panel |

|

1pc |

China |

|

|

|

2pcs |

China |

|

7.Spare Parts List

|

No. |

Item Name |

Quantity |

Photo |

|

1 |

Screwdriver |

2pcs |

|

|

2 |

hexagonal wrench |

1set |

|

|

3 |

adjustable wrench |

1set |

|

|

4 |

Screws and nuts |

Bulky |

|

|

5 |

Oil bottle |

1pc |

|

|

6 |

Tool box |

1pc |

|

- Medical Pouch and reel making machine

- Cap Making Machine

- мasк Making Machine

- Shoe Cover Making Machine

- Boot Cover Making Machine

- Sleeve Cover Making Machine

- Plastic Apron Making Machine

- Protective Clothes Making Machine

- PE Liner Making Machine

- Ear Cover Making Machine

- Plastic Glove Making Machine

- Non woven shorts making machine

- PE plastic long arm glove machine

- bed sheet folding machine

- dental pad making machine

- Medical Rescue Blanket Making Machine

- Non woven toilet seat cover machine

- curtain making machine

- Slipper making machine

- Bag-making machine